Our anilox rollers are currently available with the following 7 different engraving options:

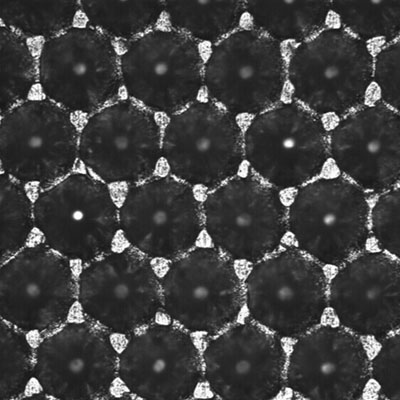

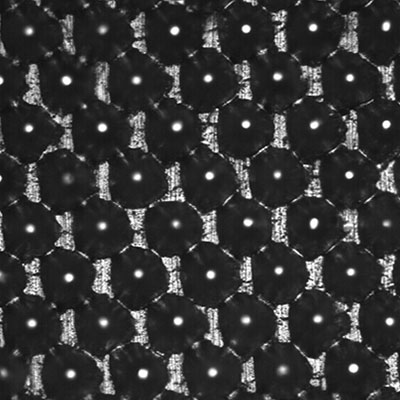

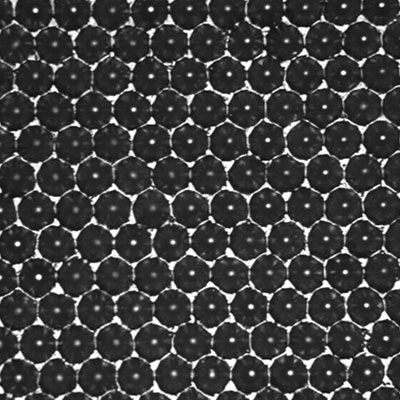

Hexa 60°: Our well-established standard engraving option that allows you to achieve high-quality printing results in the flexographic printing or coating industry.

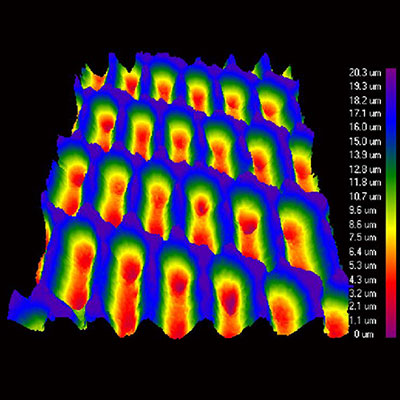

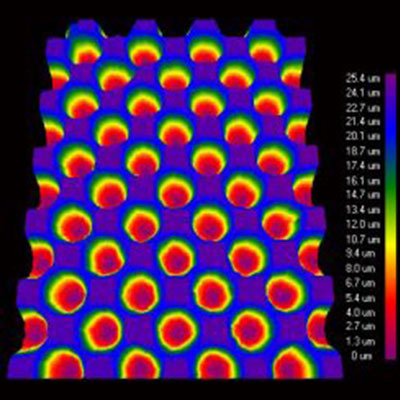

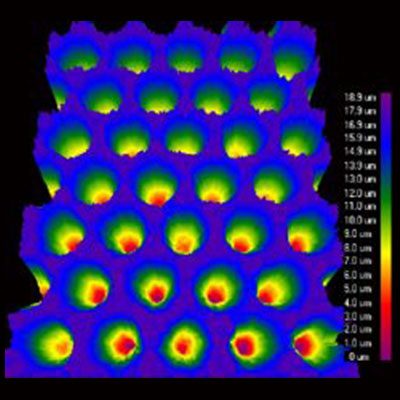

SteppedHex®: Our innovative SteppedHex engraving opens up the possibility to increase the ruling without losing volume due to a unique cell connection. As a result, you print a finer screen and yet do not have to accept any significant loss in solid ink density. You can use this engraving technology with all ink systems.

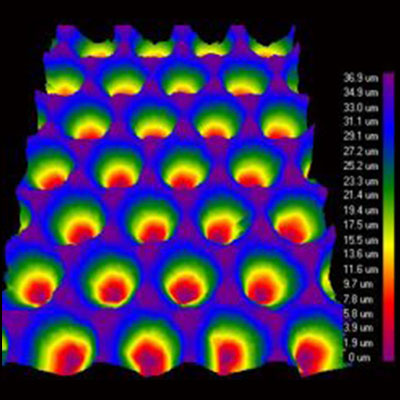

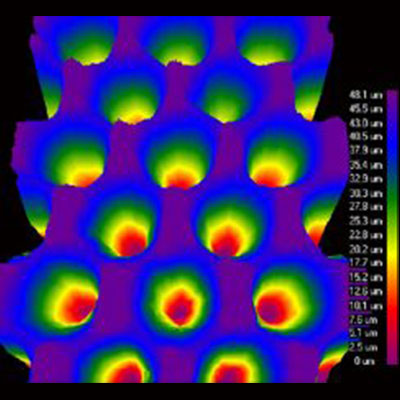

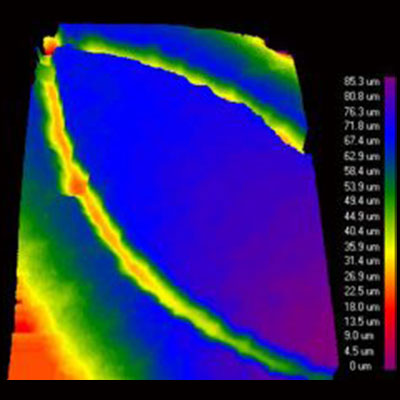

H.I.T.: Our H.I.T. engraving gives you that extra portion of white coverage. It opens up new possibilities for opaque white, varnish and special colors. Behind our H.I.T. engraving is a classic Hexa 60° anilox roller engraving, which is characterized by an optimized cup geometry. With our H.I.T. engraving you realize a higher ink transfer with a lower ink quantity. We can recommend this engraving technology especially for coating units in offset printing and for coating machines.

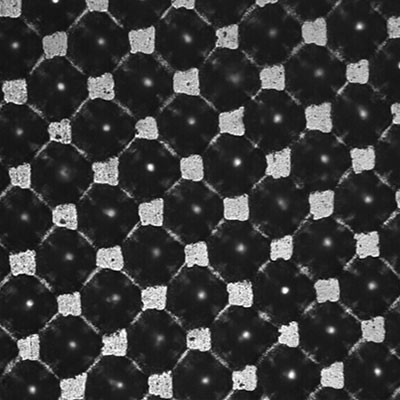

Diamond 45°: Diamond 45 is one of our first engraving technologies and has meanwhile been technologically replaced by Hexa 60°. However, we still recommend the use of Diamond 45° in special applications.

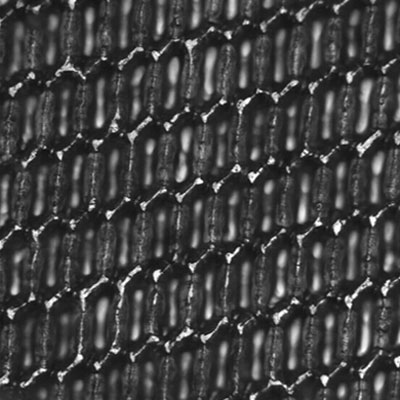

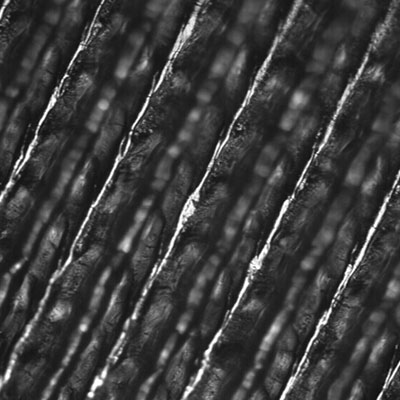

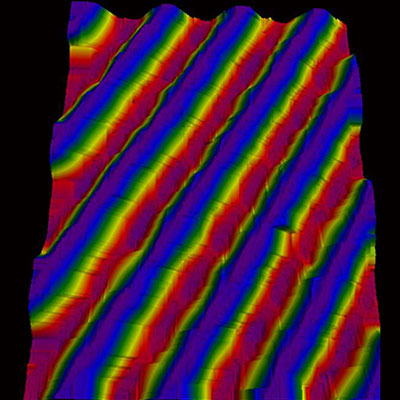

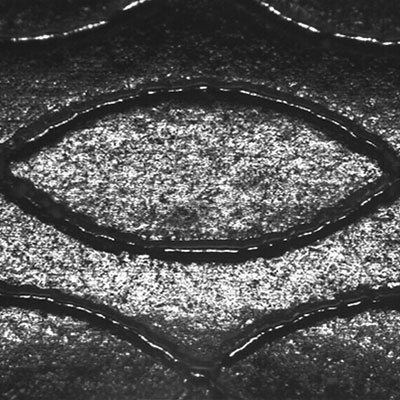

Trihelical: Trihelical is an open engraving technology (also called Haschur) which serves to extend the standard engraving spectrum or as a technical alternative. The open engraving line structure gives you very good carryover. If you tend to produce large-area prints and coatings, we particularly recommend this form of engraving.

Full-HD: Do you need high-resolution print results? Then this Full-HD engraving technology is just right for you. Our HD-ready or full-HD anilox roller engravings make printing in flawless quality possible for you. Additionally, our HD anilox roller engravings are Esko-certified.

Customized Engraving Technology: Our Customized Engraving Technology is a tailor-made anilox roller solution that is specifically designed to meet your requirements. Using individually designed TIFF data, we can engrave your customized solutions on our lasers. Our Customized technology is the right choice for your special shapes and applications.