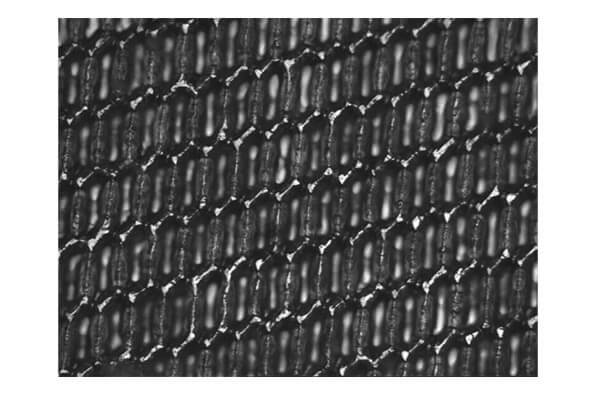

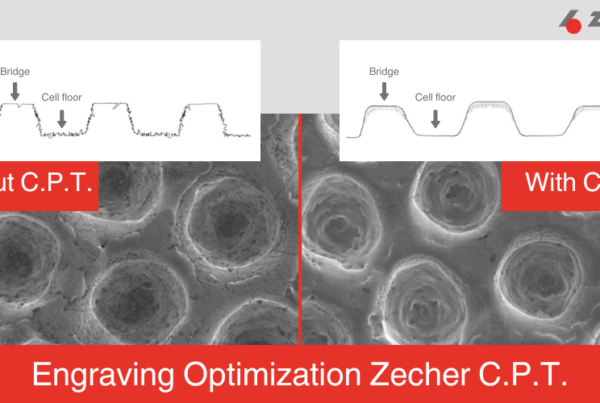

Since the launch at last year’s Drupa event, the sales of SteppedHex anilox rollers have grown three-fold. The optimized printing results speak for themselves. Our SteppedHex engraving has already attracted a lot of interest from various parts of the printing industry at last year’s Drupa event. This tried-and-tested anilox engraving technology developed in-house is based on an application of the parameters of 60° engraving, while offering an alternative to it and additional benefits. SteppedHex engraving assists the printer’s task with improved drainage of the anilox roller cells to deliver optimised printing results. The anilox cell geometry, which incorporates a special offset pattern, is subject to the corresponding German registered-design and patent protection. This optimised drainage performance achieves higher resolution and homogeneous ink-transfer, as well as making the anilox rollers easier to clean. Our anilox engraving is suitable for all inking systems, while offering advantages that are likely to create cost-savings with respect to conventional engraving techniques. Sales of our SteppedHex anilox rollers have grown three-fold since the launch at last year’s Drupa show, and our customer feedback is consistently positive. As more and more printers are expressing their interest in the possible range of deployment of SteppedHex technology as an alternative to conventional hexagonal engraving, we expect this innovative technique to become a more firmly established part of the market.

Find contact person