Zecher GmbH is a leading international manufacturer of anilox rollers made of chrome and ceramic. With continuous further developments and printing technology innovations, Zecher can now look back on more than 70 years of experience in anilox roller production. At its headquarters in Paderborn, Zecher produces more than 12,000 engraved anilox rollers per year.

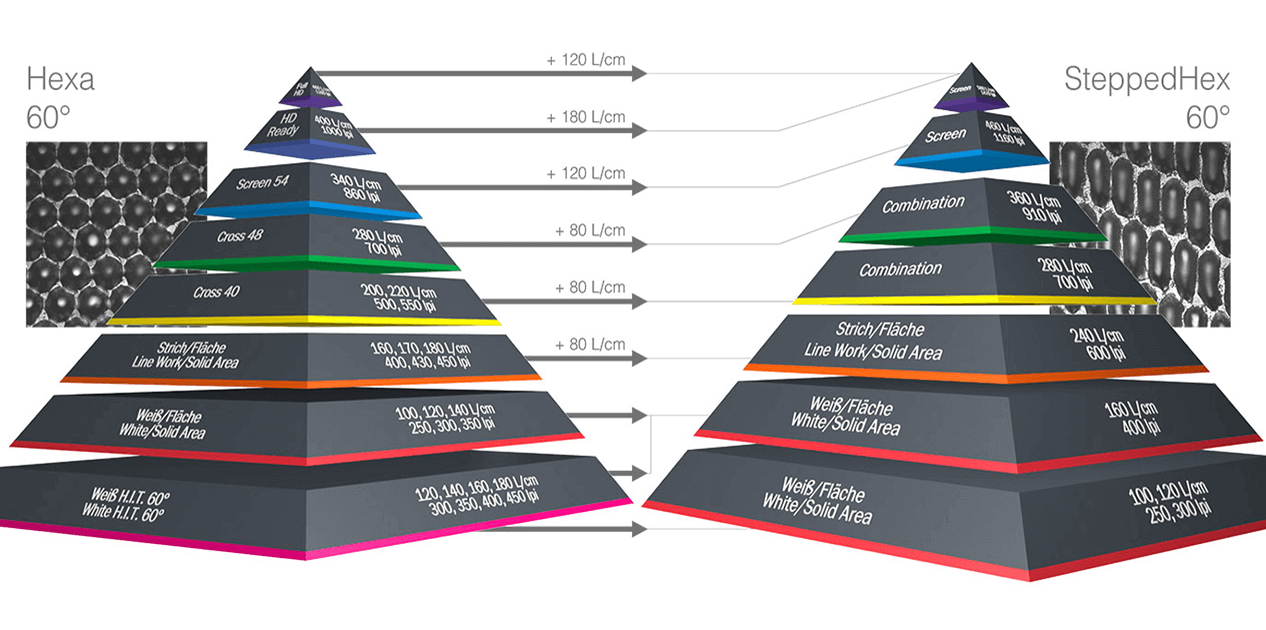

The company’s SteppedHex engraving, which was presented at Drupa in 2016, has established itself as an alternative to conventional hexagonal engraving and is becoming increasingly popular.

Many complementary advantages over conventional engraving

The specially developed and tested SteppedHex technology is based on the application parameters of hexagonal 60° engraving and offers additional advantages as an alternative to conventional engraving. It helps the printer achieve optimized printing results with improved emptying behavior of the anilox roller cups. The cell geometry is arranged in a special offset and is protected in this form as a German utility model by Zecher. The engraving is based on the well-known 60° angle with a connection of only three conventional cells lying one behind the other. In order to make the best possible use of the advantages of this open engraving form, the resolution levels (L/cm) have been ideally matched to the respective volume and application range.

In addition to higher resolution, the optimized emptying behavior achieves homogeneous ink transfer and easy cleaning of the anilox rollers. This anilox roller engraving is suitable for all ink systems and can also save costs thanks to its advantages over conventional engraving.

The response from the printing industry has been excellent and customer feedback consistently positive. Sales of SteppedHex anilox rollers have increased significantly since the presentation at Drupa 2016. More and more printers are interested in the potential range of applications for SteppedHex technology, so it is to be expected that this innovative form of engraving will continue to establish itself in the market.

SteppedHex engraving offers the following technical advantages:

- higher linearity of the anilox roller, without significant loss of volume

- smooth running of the doctor blade on the anilox roller surface

- optimum pressure nip ratios due to specially offset engraving

- unique cell shape improves emptying and cleaning

- adapted resolution levels (L/cm) and the specific offset enable optimum support of the printing form, even in the higher resolution screen

- application with all ink systems

- particularly homogeneous transfer of white, varnish, gold or silver in printing and with special media in coating

These technical advantages lead to optimized printing results, which are confirmed by the numerous successfully implemented SteppedHex projects of the anilox roll manufacturer in cooperation with customers.

Learn more about our innovative SteppedHex technology or contact our sales team directly to discuss your individual SteppedHex engraving needs.