Zecher & HUECK FOLIEN develop the best solution for coating. SteppedHex makes optimized performance possible.

Zecher & HUECK FOLIEN develop the best solution for coating.

SteppedHex makes optimized performance possible.

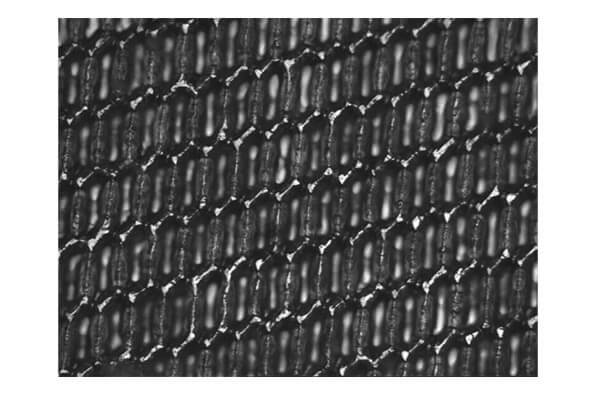

Since our foundation in 1948, we have already driven many innovations. One of them is the SteppedHex engraving technology, which is based on application parameters of the conventional hexagonal 60° engraving. Being more than just an alternative, this special engraving boasts additional benefits. With an improved emptying behavior of the cells, the SteppedHex engraving helps the user to achieve optimized results. Numerous of successful SteppedHex–projects in close cooperation with many customers are a testament to this.

Finding the best solution together with the customer for high gloss lacquering on foils

One of these projects was implemented at the end of 2017 together with the development department of HUECK FOLIEN, with the target of achieving the best possible transfer and coating behavior for various applications. Up until then, the company had only been using hexagonal or tri-helical engravings for both their chrome and ceramic anilox rollers.

Initially evaluating the SteppedHex engraving at the laboratory facility, one obtained exceedingly good and homogenous coating results.

Thereafter, the project “SteppedHex Engraving” was also implemented on the production line. Also here, the significant improvements in the process were clearly visible furthermore convincing the staff at the production facility.

More in-depth tests ensued which resulted in the selection of two further engraving specifications for new fields of application.

A special “Zecher Anilox Roller Inhouse Training” was held at the beginning of 2018 to involve the production staff at HUECK FOLIEN even more closely in this development process.

Optimal results with SteppedHex engravings

Mr. Jörg Rohde, the Head of Application Technology at Zecher, explains the cooperation with HUECK FOLIEN: “Until now, in the area of coating, only well-established specifications have been in use. For the ceramic anilox rollers these are the classic hexagonal 60° engraving and the open-cell tri-helical engraving. In direct comparison, the SteppedHex technology convinces with its specially offset cell geometry and the increase of the screen ruling without loss of volume. With this engraving technology, it is possible to achieve an exceedingly good transfer, as well as an especially homogenous coating result. In addition to this, the cleaning behavior is furthermore improved, which is a real advantage for special media.”